Heat represents one of the hardest to decarbonise sectors in the UK. The entire energy network, from gas transmission to domestic boilers, has been built to suit fossil fuels. Only biomethane can act as a direct substitute for fossil natural gas – without requiring extensive changes to installed infrastructure or disrupting households across the country – and can delivers significant decarbonisation immediately.

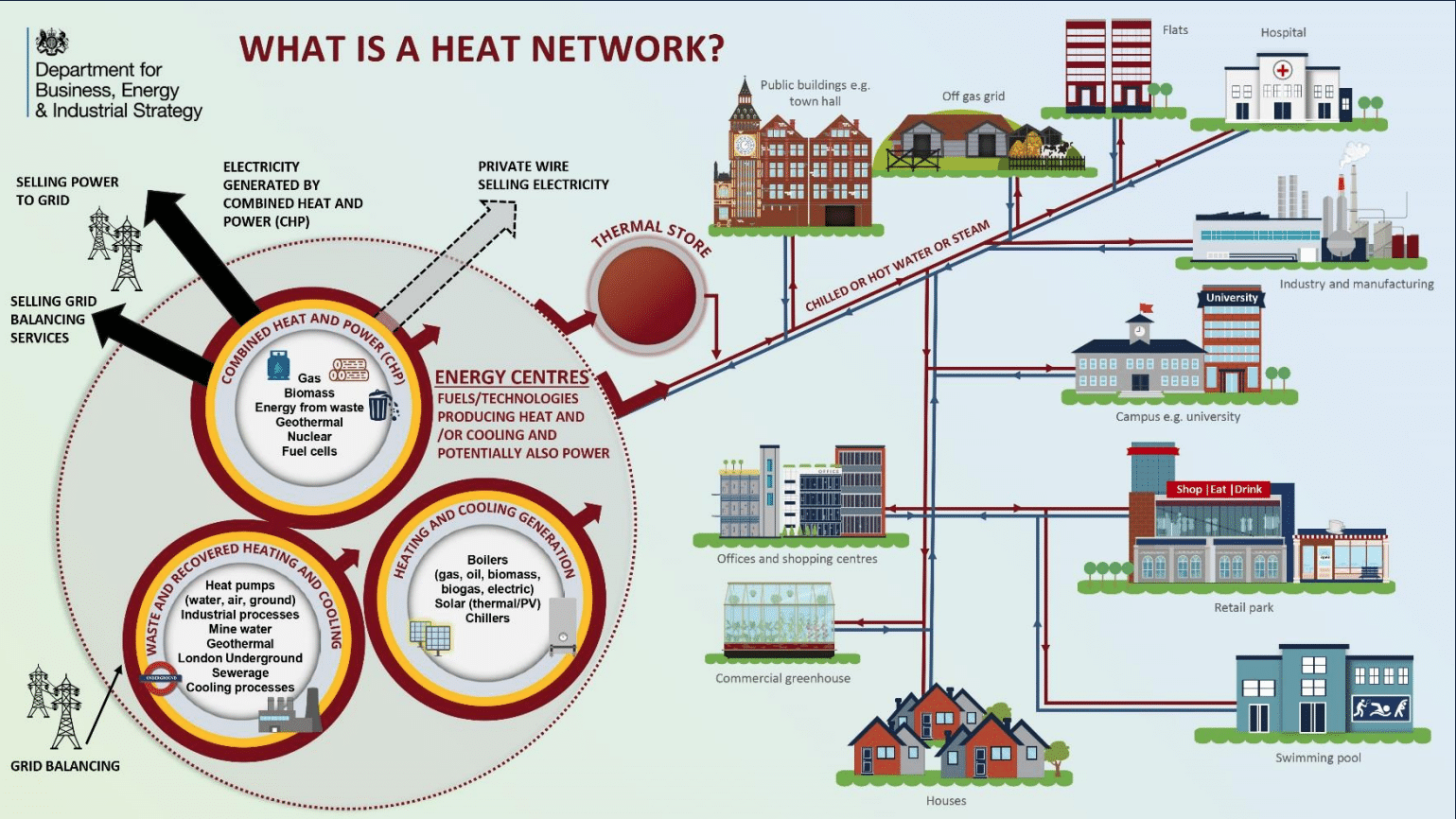

Currently biogas is most commonly used as a fuel in combined heat and power (CHP) units, in part due to past financial incentives regime. These units generate renewable electricity and primary heat, which can be exported to the national grid and piped within local heat networks, respectively. A small proportion of this energy also used to operate the AD plant itself.

Heat from the gas engine (or indeed a direct fire boiler) can be used to provide cooling as well as heat. This approach is known as trigeneration or combined heat, power and cooling (CHPC).

Policy

ADBA is lobbying for sufficient financial support to maintain industry growth and increase its total capacity to treat organic wastes. Due in part to our efforts, the government are launching the first support scheme specifically for the AD industry and its production of biomethane. The Green Gas Support Scheme (GGSS) is set to channel up to £150 million per year to new AD plants, driving the gas grid decarbonisation. Opening for applications in Autumn 2021, the GGSS will follow on from the highly successful Renewable Heat Incentive (RHI), which supported the construction of over 100 biomethane plants. ADBA are in continued discussions with government to help ensure the GGSS effective supports the industry.

Did you know?

- When used for heat, biomethane generated from residual wastes could produce GHG savings of up to 92% compared to natural gas.

- ADBA estimates 5.3MWth of cogenerated heat is currently vented. Total wasted thermal capacity is estimated at 135MWth, which if captured and used could abate 170,000 tonnes of carbon.

- 5% of homes – four million – are off-grid but responsible for 23% of carbon emissions associated with housing. Biogas could address this.

Case study - HRS Heat Exchangers

Evaporator design makes best use of waste heat

A scraped surface evaporator supplied for digestate liquor treatment at Scottish and Southern Energy’s (SSE) Barkip anaerobic digestion plant has played a key energy saving role in recovering waste heat, which is used in the process as well as being exported as renewable energy.

HRS Heat Exchangers Limited, a leading heat transfer specialist for the process industry, has delivered a scraped surface vacuum evaporator, which is operating at the Barkip anaerobic digestion plant at a former landfill site in North Ayrshire. The plant was the first of its kind to incorporate a digestate processing stage. Waste heat from the CHP engines is used to concentrate the liquid fraction of the digestate into a nutrient rich liquid fertiliser.

HRS technology enables the Barkip plant to process 75,000 tonnes of waste annually, in a plant setup that also produces around 2.5MW of electricity for the Scotland’s renewable energy industry.

At the heart of this technology is HRS’ Unicus dynamic scraped surface heat exchanger that ensures that any high organic load in contact with hot surfaces does not lead to fouling, which is a common problem when organic digestate is evaporated.

For many environmental applications, standard evaporation technologies are not ideal and do not achieve the desired optimum thermal and waste recycling performance. The HRS patented technology provides continuous cleaning for the evaporator walls so that plant can work continuously with very little maintenance, at times for more than six months.

The evaporator from HRS was chosen not just for its operational performance, but because the quality of the team behind the product is excellent,” said Pat Howe Project Manager Barkip Anaerobic Digester Plant. “When we made enquires about the product and its suitability we were immediately offered the opportunity to see this type of equipment in operation. As a customer that level of confidence in a product with a proven track record is vitally important

When SSE commissioned Scotland’s largest biogas plant last summer, the generator became the first energy company in the UK to commit to construction and operation of an anaerobic digestion biogas plant of this type.

The Barkip site will be capable of processing around 75,000 tonnes of waste annually, producing around 2.5MW of electricity that will contribute towards Scotland’s renewable energy targets. Feedstock materials for the plant, which are mainly selected to divert waste away from landfill, include waste foods, manures and organic effluent sludge’s.

Anaerobic digestion is a natural biological process that uses bacterial cultures within enclosed silo tanks to generate methane-rich biogas from waste organic materials and energy crops such as grass silage. The Barkip plant will use a high-temperature thermophilic two-stage digestion process supplied by Danish technology firm Xerg, which will see heat being captured from the generation process and used to concentrate the liquid fraction of the digestate into a nutrient-rich liquid fertiliser.

Commenting on the success of the project, Steven Pither, Managing Director, HRS Heat Exchangers Limited said,

HRS is proud to associate itself with such a pioneering project. Our self-cleaning evaporator system has the capacity to overcome fouling issues in a digestion plant. We’re proud to operate in a sector where innovation can save energy, reduce waste, and CO2, and improve final product quality without harming the environment

About the process at the Barkip Anaerobic Digester Plant

Digestate from the process will first feed into a centrifuge to separate the liquor and fibre fractions. The digestate liquor is then pre-treated with acid prior to evaporation within the scraped surface heat exchangers to prevent ammonia loss within the evaporator. The volume of acid dosed is dependent on the digestate and the desired retention. Within the evaporator the liquor is concentrated to approximately 20% DS. The evaporator operates under vacuum at temperatures between 50°C and 70°C. Heat required for the process is provided by the combined heat and power plant (CHP). This application of heat is eligible for the RHI.

The evaporators at Barkip will be fed at 10,800 kg/h and produce 1565 kg/h of concentrate. The concentrate can then be mixed with the separated digestate fibre to produce a nutrient rich solid fertiliser for export. Distilled condensate for the process will be recycled as process water with any excess discharged to sewer.

For this application the heat exchanger tubes have been constructed from Duplex steel due to the high content of chlorides within the waste feed.

Key Benefits

- Nitrogen retained within the digestate

- Concentrated fertiliser reduces transport costs

- Additional income from RHI

- High levels of N/P/K retained within the digestate.