Huber UK is pleased to announce the sale of their first Longitudinal Grit Trap for removal of grit and glass from Anaerobic Digestion soup in the UK. The design based on their well proven municipal grit trap has been installed in 16 AD locations in Europe with 11 units supplied to 1 AD client. The AD version for Biosolids is a heavy duty version of the Municipal Grit traps and there are 144 municipal units installed.

The problems of grit and glass collecting in Digesters, tanks and causing wear in pumps and pipework is considerably reduced by installing a correctly sized grit trap. Huber has removed up to 3% of the flow as grit and glass in their AD grit trap.

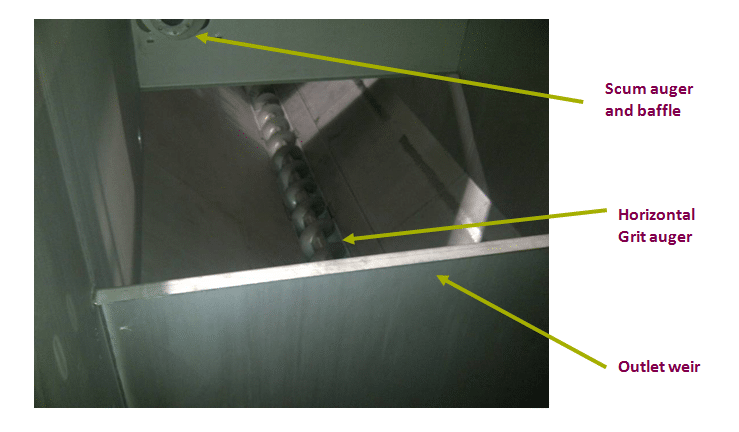

Figure 1 Grit Trap for 50M3/hour digestate at 10-14% DS

The flow is controlled in a constant velocity channel with a weir across the end of the channel. The grit settles in the base and is bought to the collection box by a horizontal auger. The horizontal grit auger travels in a counter flow direction and is pulsed to release biomass.

Air is injected into the base of the tank (far side of Figure 1) to give a circular motion in the tank across the flow. This keeps the biomass in suspension and facilites the scum to be circulated into the scum auger (Option).

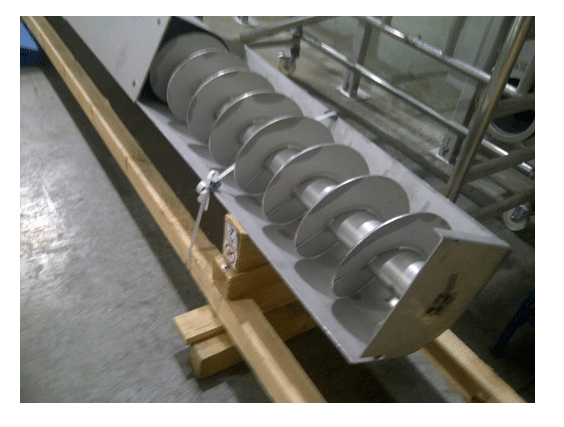

Grit is raised above the water line by an inclined auger and discharged either right or left into a skip.The auger drains and slightly compacts the grit. Huber can supply a grit washer as a retrofit to wash out any Biomass entrapped in the grit.

Figure 2 View inside grit trap

Figure 3 Grit Auger removed for transit