Your AD plant can increase its revenue by over £100,000 per year, by simply identifying…

Optimising the AD process: every little helps

Our industry magazine, published this week, has highlighted how AD plants should be optimised, with tips from the experts.

Areas mentioned included:

- Metering of feedstock input volume and measurement of dry matter

- Metering and analysis of gas

- pH monitors

- Temperature probes

- Titration tests

- Daily machinery checks

- Plant cleanliness and high standards of housekeeping

- Monitoring loading rates and residence times

- Controlled testing of the impacts of changing feedstocks, dry matter content and temperature

- Use of trace elements and enzymes

These suggestions shouldn’t need pointing out. They clearly do, however, judging by some of the volatility in the energy output from many plants.

But once all of these existing tips are followed, how can performance then be improved?

At ADBA we’re keen to work with the academic community to develop what will be the next generation of ‘performance tips’. As the above list demonstrates, with AD there is not likely to be one ‘silver bullet’ that will transform the performance of the sector. But there may be 100 improvements that will advance different elements in the process: in AD every little helps!

So for the Research and Innovation (R&I) Hub at UK AD & Biogas on day 1 (6 July) we have assembled a group of academics and innovators that will add to the science in these and other areas:

- Professor Sandra Esteves of the Wales Centre of Excellence for Anaerobic Digestion will open the session at 11.15 to talk about how an understanding of microbes can speed up the digestion process. Sandra has a vast experience of delivering academic projects for the UK AD industry and in advancing the fundamental science behind what we do, so we’re delighted to have her speaking.

- Edgar Blanco of Anaero Technology. Edgar is an inspiration! He has developed, among other technologies, a feedstock testing digester that replicates the actual operation of a digester. His background working on the operation of one of the first AD plants in the UK, as well as his inventiveness, has given Edgar an excellent insight into what can improve the accuracy of testing and save operators precious time.

- Dr Rafaella Villa of Cranfield University will ask whether there is a future for enzymatic addition in the AD and landfill sectors. They can increase biogas production – but by how much? Encouragingly, Rafaella will cover the costs as well as the benefits, which is something many in the industry ask academia to do more of.

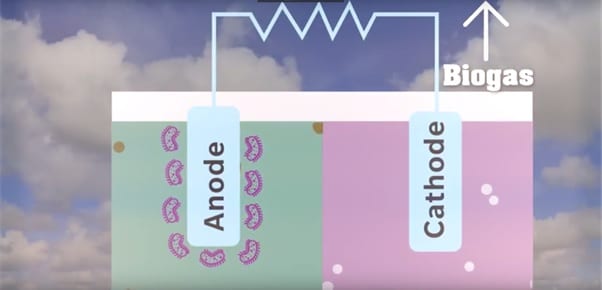

- H2AD have developed a hybrid of Anaerobic Digestion (AD) & Microbial Fuel Cell (MFC). Unlike traditional AD, the H2AD technology is on a micro scale. The H2AD system employs innovative anode & cathode materials which has allowed a cost reduction of 90% compared to traditional MFCs.

If you’re interested in extracting more from existing feedstocks, doing it faster, or for lower cost, come and listen to this exciting session on the future of operational performance.

Some photos as a snippet of what speakers will be talking through:

Anaero’s semi-continuous lab scale reactor

A cellulase enzyme

H2AD microbial fuel cell