Your AD plant can increase its revenue by over £100,000 per year, by simply identifying…

NPL: Solving the siloxane measurement problem

Project demonstrates benefits of traceable on-line measurement of siloxanes in industrial biogas

Solving the siloxane measurement problem

Of all the hurdles the biogas economy has faced, the challenge of impurity measurement remains at the forefront of industrial and scientific interest. A recent project funded by the European Metrology Research program for Innovation and Research (EMPIR) has taken steps towards providing a solution to one of biggest measurement challenges in biogas quality.

There are currently no standardised methods for the measurement of siloxanes in biogas or biomethane, so scientific research projects such as this are proving vitally important for underpinning the growing biogas economy. During the novel 18 month project, the UKs National Physical Laboratory (NPL) worked in collaboration with UK based company Protea to demonstrate the benefits of traceable online measurements of siloxanes in industrial biogas. The results indicate that moving towards real-time measurement provides a large advantage over more traditional methods, which have been plagued with issues.

The siloxane challenge

Amongst the diverse impurity content of biogas, siloxanes are amongst the most problematic both in terms of measurement challenge and their harmful effects on infrastructure. Siloxanes can cause irreversible damage to gas processing equipment, as abrasive silicon dioxide deposits are formed during combustion. The fouling of thermocouples and oxygen sensors has also been observed, causing feedback errors and efficiency loss.

Siloxanes are a relatively new impurity found in biogas, as their use within household products has gradually increased over the last few decades. They are now commonly added to products such as cleaning agents, deodorants and cosmetics to improve their consistency and performance.

Figure 1: Molecular structure of L2, L3, D4 and D5 siloxanes (C: black, H: white, O: red, Si: teal)

Once disposed of, these products become part of the waste streams that are typically used for biogas production. Due to their volatility, the siloxanes become entrained with the biogas during the digestion stage, and must be removed to below a threshold level before the biogas can be safely used to produce energy. This ‘total silicon’ limit level varies by application, and the limit values themselves are still under scrutiny at European standardisation level.

The need for a new ‘gold standard’

The current ‘gold standard’ for siloxane quantification involves collecting samples within sampling media such as sample bags, which are then sent to laboratories for analysis, and results provided after several days. Although offline methods do not require an initial investment, over time they prove to be an expensive technique. Looking beyond the figures reveals a bigger problem, as studies have widely reported problems with the short-term stability of siloxanes within media such as sampling bags. This often leads to large differences in results when samples are sent to separate laboratories, as the sampling method fails to provide a representative view of the siloxane content. So while the laboratory based measurement techniques may be accurate, the sample they are measuring is often compromised as the technique is not fit for purpose.

Spectroscopic solution

UK based company Protea has developed an instrument that utilises Fourier Transform Infra-Red (FTIR) detection to identify and quantify siloxanes in real-time. The full spectrum technique utilised by their ‘AtmosFIR’ instrument also allows for the measurement of methane and carbon dioxide, which are the main biogas components.

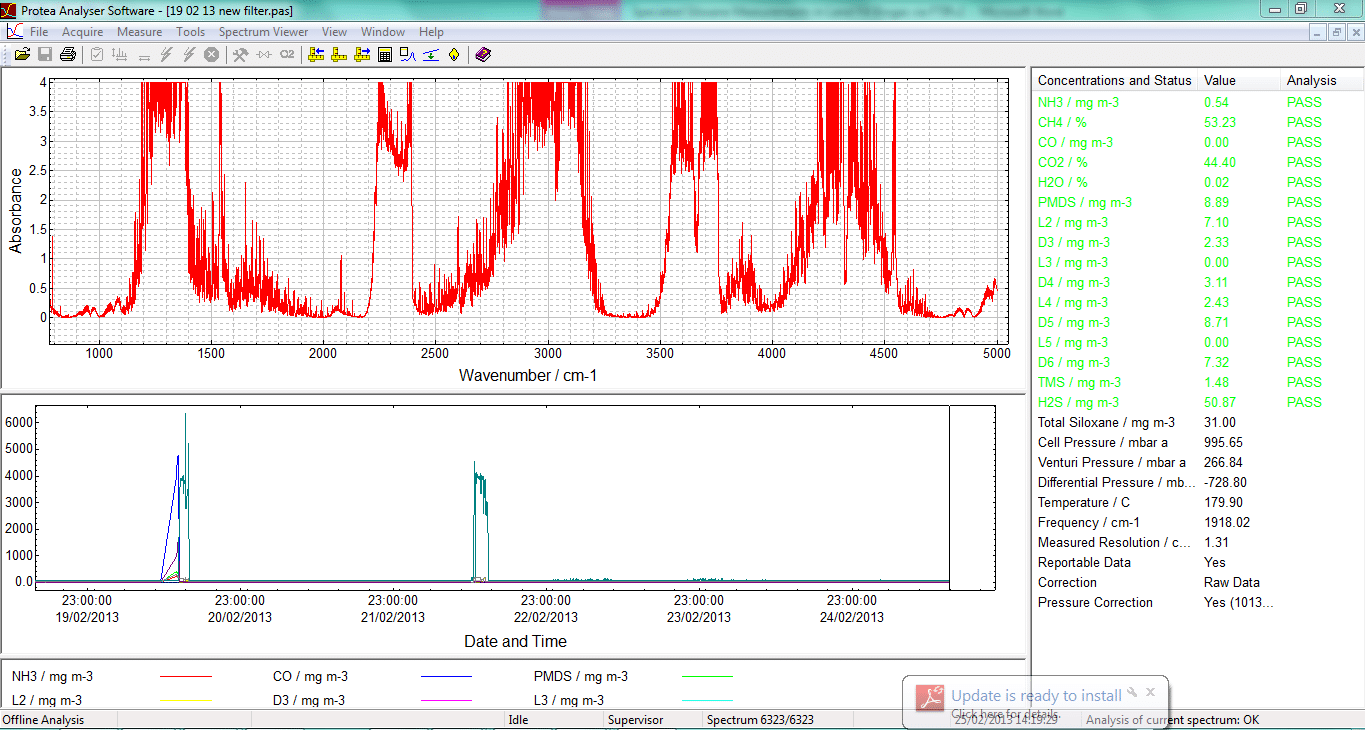

Figure 2: FTIR spectrum showing siloxanes in biogas and AtmosFIR instrument

Although siloxanes appear similar to the detector, there are small changes in response due to differences between the molecules. This enables each siloxane to leave a unique fingerprint, and allows for multiple biogas components to be measured simultaneously, providing a holistic measurement solution.

Traceable reference siloxane standards

In order to validate Protea’s FTIR technique, traceable gas standards containing siloxanes in biogas were prepared by NPL in order to provide a reference. NPL is the UK's national standards laboratory, a world-leading centre in the development and application of highly accurate measurement technology. The gas and particle metrology group has refined their techniques through over six years of biogas impurity research, and their reference standards are at the cutting edge of accuracy.

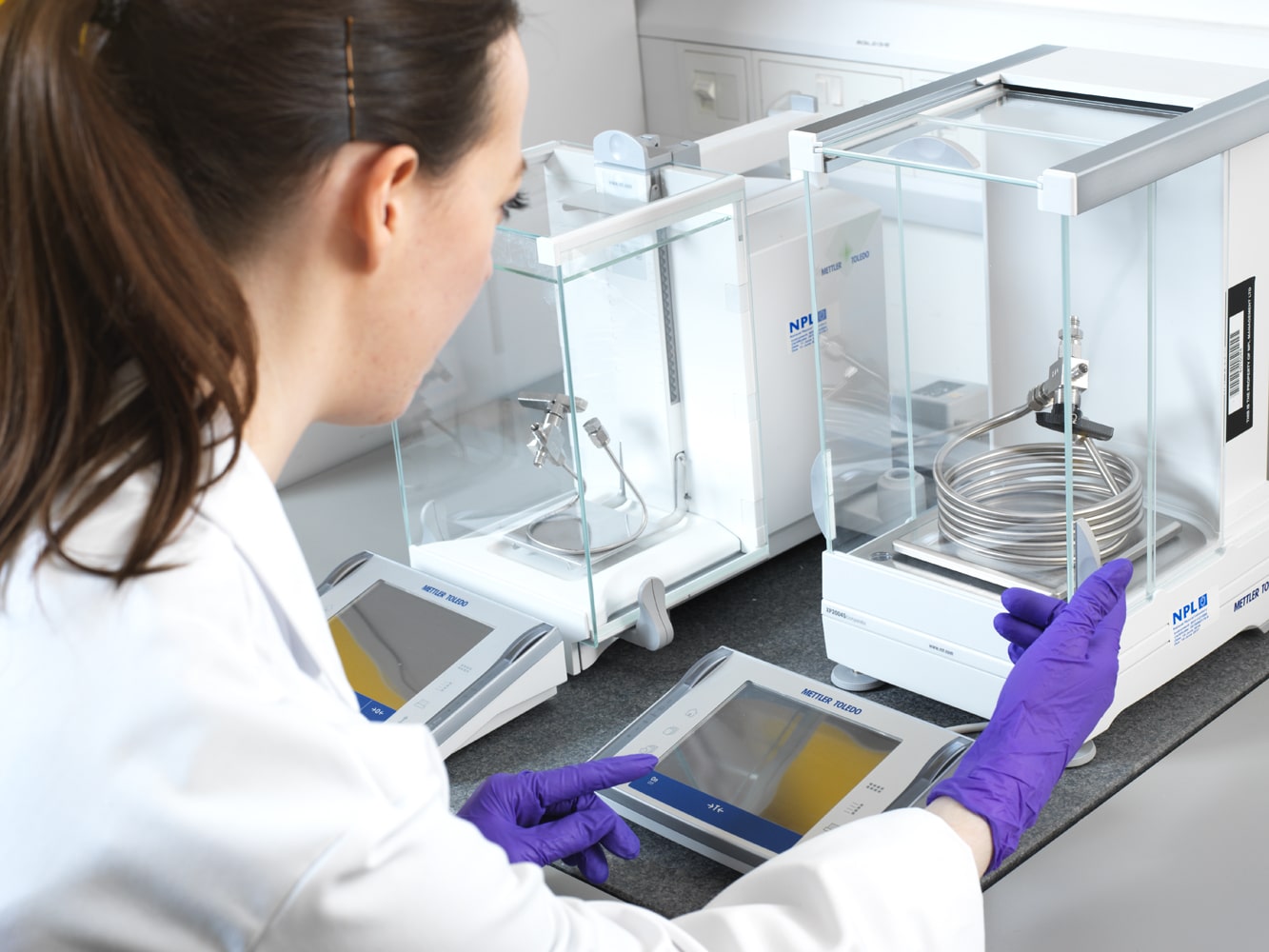

Figure 3: Reference mixtures are prepared by weighing each component

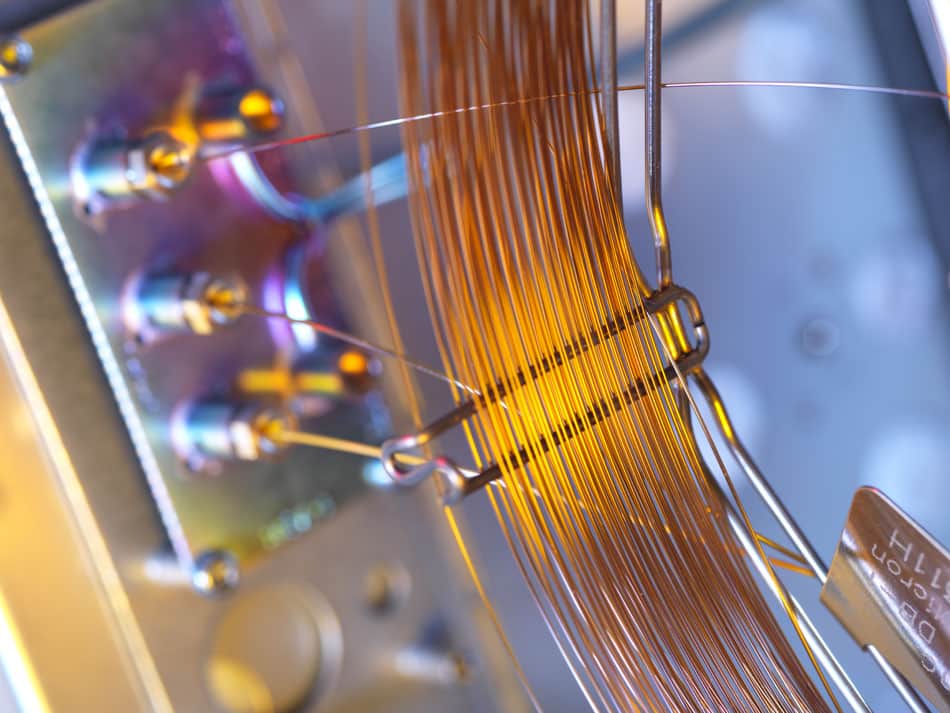

Traceability is vitally important, as it ensures that measurement results are valid through using an unbroken chain of comparisons back to national standards. In this case the mixtures are traceable to the SI kilogram, as components are individually weighed using high precision balances as they are added to the gas cylinder. The standards are then validated using a high precision gas chromatograph, which separates the siloxanes on a thin capillary column before detecting them with a mass spectrometer. In contrast to Protea’s FTIR technique, this lab-based solution is not appropriate for performing online measurements due to its high cost and maintenance requirements. It is barriers such as this that has thus far posed a challenge to biogas upgraders, as there is often a trade-off between accuracy and cost.

Figure 4: Lab based techniques are accurate, but expensive

Field trial

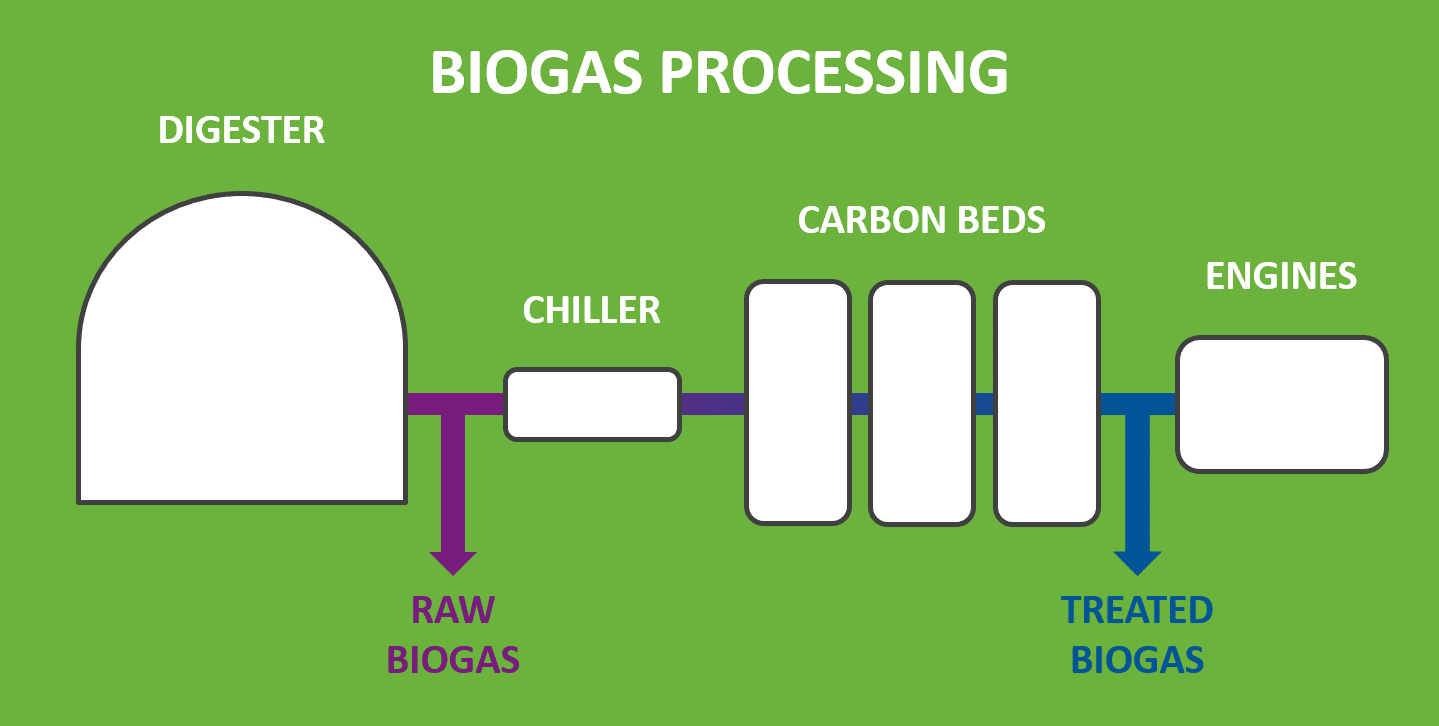

The AtmosFIR instrument was taken to a UK based wastewater treatment plant. The plant uses anaerobic digestion to convert waste sludge into biogas, which is burnt in gas turbines to generate renewable energy. Raw biogas from the digester is upgraded using a series of activated carbon beds before it is fed to gas turbines.

Figure 5: Plant schematic showing sampling points

The beds undergo a nine hour regeneration cycle, in which a bed is taken off line after six hours for cleaning. The biogas flow is diverted onto a clean bed whilst the previous bed regenerates to ensure there is no interruption to the process.

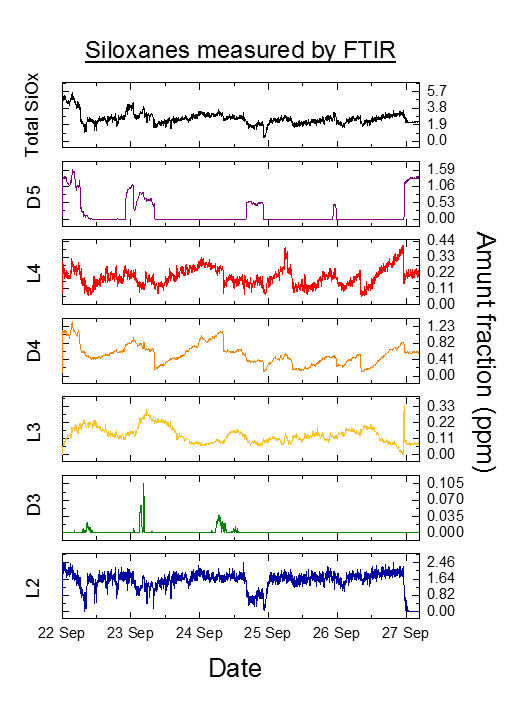

Real time data collected from Protea’s instrument clearly captures how this regeneration cycle affects the amount fractions of individual siloxanes within the biogas. D4 siloxane in particular can be seen to follow a clear rise and fall pattern, which aligns with the bed regeneration schedule.

Figure 6: On line measurements captures the trends that grab samples may miss

The real time data also captured a surprising result when it was switched to measure raw biogas (see 27th Sep in graph). Although some of the heavier siloxanes were seen to increase as expected, the total silicon was lower overall in the raw biogas. NPL and Protea chemists have theorised that this is likely due to the chemistry of the carbon beds and a feature of aging material. After contacting the site it was discovered that the carbon beds were indeed due for replacement, which served to explain the anomalous result and highlight the advantage that continuous monitoring would provide

During the field trial, NPL’s traceable gas standards were used to perform calibration checks on the AtmosFIR. Traceability in instrument calibration is important for providing confidence in results, so a full lab-based validation of the AtmosFIR took place at NPL in advance of the trial. It is through this mechanism that the results are validated, through an unbroken chain of comparisons back to the SI.

Figure 7: On line sampling

Conclusion

The growing industry need for the fast and accurate measurement of biogas quality is a vital one to address. Impurities such as siloxanes currently have no standardised methods for their quantification, so it is important to develop new solutions to feed into future standardisation. The development and validation of on line instruments such as Protea’s AtmosFIR are taking important steps in moving the biogas quality framework forward. The monitoring of individual siloxanes in real time is currently not widely practised, but in this case has proved valuable by highlighting breakthrough of lighter siloxanes in aging carbon beds. Direct on line measurement has the advantage of removing the uncertainty associated with existing sampling methods, which is widely recognised as one of the largest sources of error. This project has demonstrated that techniques such as FTIR provide a viable solution to the siloxane measurement challenge, revealing hidden trends that would have otherwise gone unnoticed and providing plant operators with quality assurance and a platform for process optimisation. The validation of measurement techniques such as this, will ensure that biomethane can play a significant role in delivering a sustainable and secure energy future.

This article was written by Lucy Culleton, Higher research scientist at NPL. Visit NPL.co.uk

This article was written by Lucy Culleton, Higher research scientist at NPL. Visit NPL.co.uk

Free Consultations

As part of the funding from EMRP, NPL and their partners are able to offer free sessions to support the biopgas industry by providing consultation on effective sampling of biogas and performing accurate and traceable measurements of:

- Organic impurities in biogas;

- Inorganic impurities in biogas;

- Moisture and particles content;

- Calorific value and density.

To find out more contact the project team here.