Digestate reduction using a screwpress

BV Dairy were producing 17,400 m3 of liquid waste per annum and this was tankered away in 15 tankers per week. With an aim of reducing their carbon footprint BV Dairy, with the assistance of WRAP and ETF funding, a high rate anaerobic liquid digester has been successfully built by Clearfleau Limited.

Figure 1. Plant Installation blended into landscape

The installation should reduce the carbon emission by 120,000 tonnes per annum and produce 1,539MW of electricity and 1,685MW of heat per annum.

After removing the biogas and reducing the COD the digestate is passed through a Separation system before discharge to sewer.

When it came to disposal of the digestate HUBER were asked by Clearfleau to supply a Screwpress model RoS3Q 280 to reduce the sludge to a cake.

Figure 2. Screw Press Installation

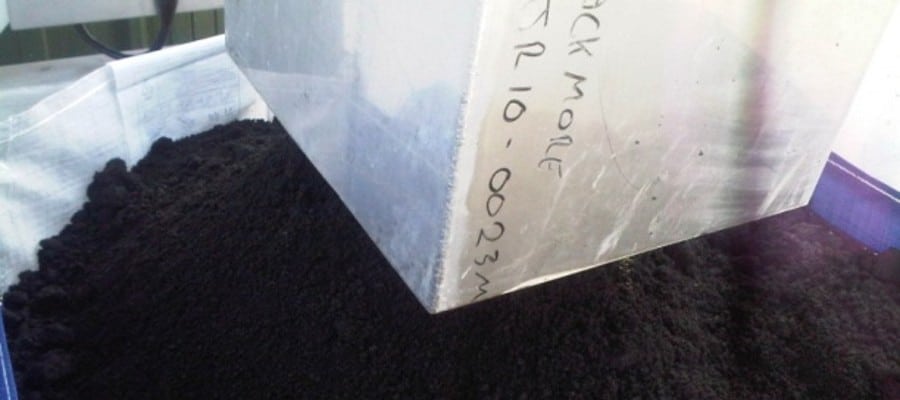

The Screwpress is fitted with a 0.37kW motor and operates at 0.6 to 1.9 RPM and produces a cake of 18-22% dry solids. The low power consumption fitted in well with the plant ethos to reduce CO².

Figure 3. Pressed Cake

HUBER also supplied the Screwpress controls, flocculent preparation and dosing and a screw conveyor to remove the cake from the Screwpress to the skip.